Greater Tulsa Area Classifieds Moderated Newsgroup > Broken Arrow

> Tools

> Compressors

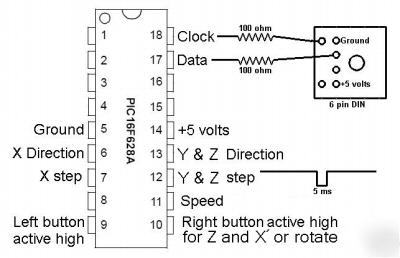

> 4 axis motion control using stepper motors and a mouse

4 axis motion control using stepper motors and a mouse

For those of you that want to build your own circuit with easy mouse input.

Freehand control of an X Y Z & X' axis using a computer mouse without the computer. Using the same precision incremental stepping motors that your printer uses to put each pixel in exactly the right place. This PS/2 mouse to motor interface will run 4 unipolar or bipolar stepper motors, 2 at a time and not tie up your computer. There is a micro computer inside. This is for precision positioning.

With 2 speeds, moving the mouse 1 MM rotates the motor 1 full step or half step. The default is half step at 2:1 ratio. To change speeds on the fly, hold the left button and click the right button or vice versa. The speed toggles on each click.

Launch any Windows paint program and sign your name on a page with the pen tool and your mouse. Now imagine trying to do that with a joystick. You have much more control and coordination with a mouse. In your case, you might be moving the page instead of the pen but it will feel so natural that the user would not know the difference. This picture of handwriting on a printer carriage is using a combination. It is moving the pen horizontally but is moving the paper vertically. It operates smoothly at a 1:1 or 2:1 ratio and as fast as the printer would.

Now with a Pan or Travel mode. Just hold the middle button (or wheel) with the left or right button and it keeps moving. You just steer it with the mouse.

A 200 step motor coupled directly to a micrometer spindle would move your device 0.0000625" per MM of mouse movement. Gear ratios can reduce that to Nano positioning.

If you don't need 4 outputs, just use what you need.

Using a bank of switches you can control as many cameras as you like including zoom with one mouse.

Some uses that I can think of include:

Positioning a microscope stage at 1 micron resolution.

Controlling micro manipulators for Electrophysiology.

Place the smallest of surface mount components.

i.e. : left button X & Y, right button Z & rotate.

Touch up circuit boards, film and microfilm.

Micro machining and polishing.

Manipulate radioactive or hazardous materials.

Aim or position police robot tools for rescue or bomb search & disposal.

Manipulate specimens for bright light inspection.

Many things on a larger scale like laser or plasma cutting and welding.

The Processor in Micro Motion Mouse Control is socketed for easy removal to use in your own prototypes. Input should be anything you can plug into a PS/2 mouse port.

We can supply the mouse, 7 to 16 volt AC or DC power supply / battery and up to .75 Amp per coil unipolar or bipolar stepper motors wired correctly but they are not included. That depends on your application.

We may be able to build / manufacture whatever device you have in mind.

If you need something a little different, say so. The software can be modified.

For specs and more info visit http://motionmouse.com